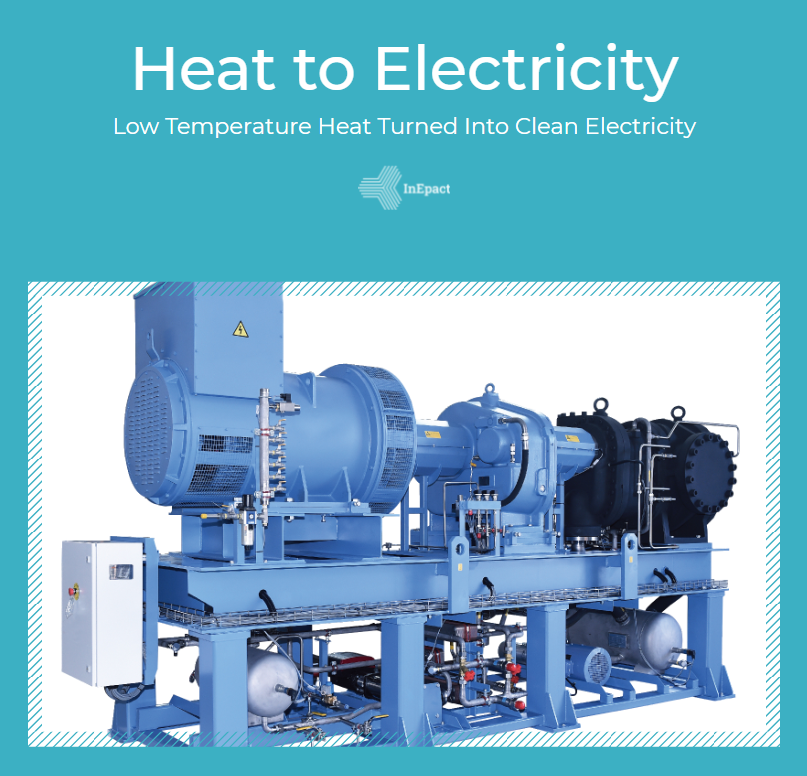

HOLISTIC ENERGY MANAGEMENT & OPTIMISATION SYSTEM

Context

The global shipping sector currently contributes about 2.5–3% to global CO2 emissions. Within the EU, the maritime sector makes up about 14% of greenhouse gas emissions from the transportation industry. In port areas, ships are one of the largest air polluters (CO2, Sox, NOx, particles). IMO introduced a new Energy Efficiency eXisting ship Index (EEXI) that poses a challenge for ship owners. Significant increases in fuel prices put additional stress on ship owners to find options to reduce energy expenses.

Challenge

HEMOS response

Impact

Discover the scientific research

This project has received funding from the European Union’s Horizon Europe research and innovation programme under grant agreement No. 101056909.

Follow our journey of capturing the lost heat!

© 2022 Copyright HEMOS project. All Rights Reserved.

This project has received funding from the European Union’s Horizon Europe research and innovation programme under grant agreement No. 101056909.

Follow our journey in capturing the lost heat!

© 2022 Copyright HEMOS project. All Rights Reserved.