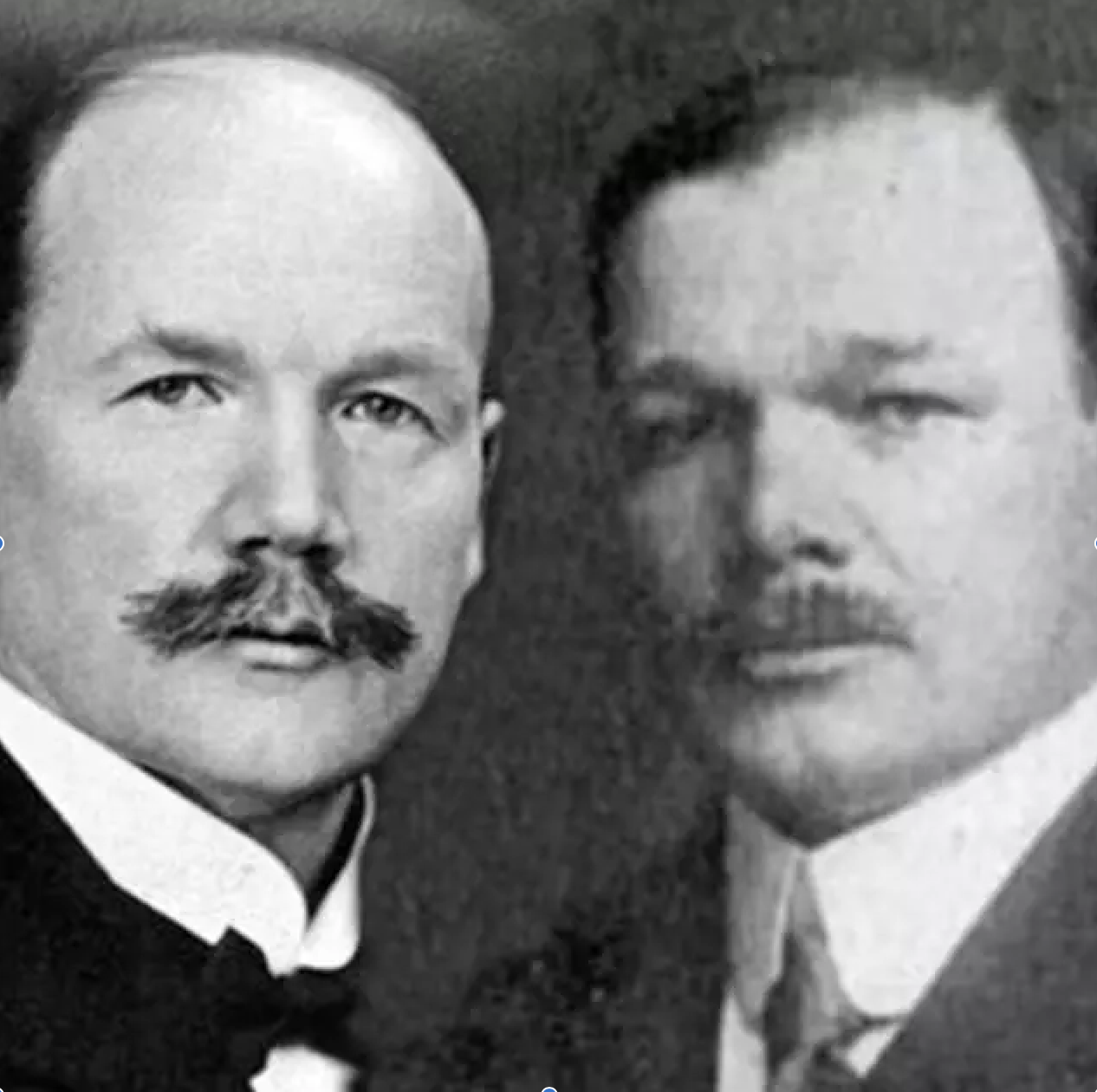

Our HEMOS project came to life thanks to the established companies and the fascinating minds in them. When discussing innovation and novel technologies, we naturally look into the future. However, while moving forward, it is also worth measuring how far we have already come. So let’s look back and recognise those who came before and showed us the way towards renewable energy production. For HEMOS project partner, Swedish company InEpact, it is their sister company, the Ljungström Brothers – founders of Svenska Rotor Maskiner (SRM).

Fredrik (1875–1964) and Birger Ljungström (1872–1948) of Sweden are internationally recognised inventors and designers in mechanical engineering and materials science. They registered hundreds of patents and established companies to exploit their innovations. Their work on the design of steam turbines for generating electricity was particularly significant since they jointly patented the Ljungström Turbine in 1908.

Endorsed by Alfred Nobel

In 1895 Frederick developed a steam generator that Alfred Nobel himself supported financially for use in steamboats. Nobel suggested they move to Britain to further their work in mechanics. Until 1903 they remained in Britain, where they opened the Ljungström Engine Syndicate Limited in Newcastle-upon-Tyne. They also developed an early milking machine for dairy farms.

But their most important invention was the double counter-rotating turbine, which they refined in stages from 1894 onwards. In 1908, they created ALA (AB Ljungströms Ångturbin) to develop their turbines. In 1913, they then began another company STAL (Ljungström Swedish Turbine Manufacturing Company to manufacture turbines at a large factory in Stockholm. They provided complete steam turbines that were more efficient and more compact than earlier models for generating electricity and driving ship propellers. They had contracts with Siemens and General Electric, to name a few.

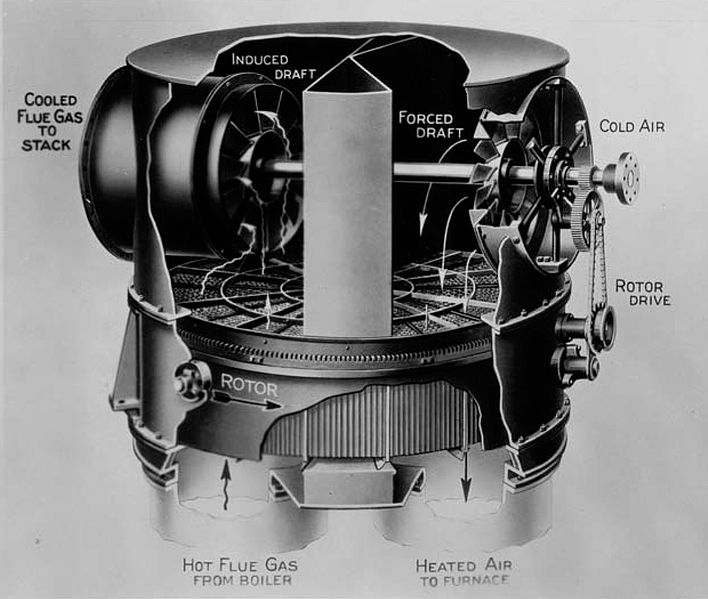

The brothers also produced inventions in several other fields, including air preheating, shale oil extraction, naval engineering, engine transmission and hydraulics. Power stations worldwide continue to use the Ljungström air preheater to save fuel, and the concept of their turbine lives on in modern designs. In 1995, the American Society of Mechanical Engineers selected it as a landmark invention. Today, it is still one of the products that have reduced carbon emissions more than anything else. It has been estimated that, since 1920, the use of Ljungström air preheaters has achieved worldwide fuel savings of over 5 billion tons of oil!

Since the 1930s, SRM compressor technology has been continually developed. SRM’s former licensees, Atlas Copco, Hitachi, IR, Carrier, York, Trane, Kobelco, and many others, are industry leaders today. Virtually all screw compressors in the world are based on SRM’s technology. With over 900 patents in 30+ countries, SRM has shown leadership and innovations in screw rotor machines and energy efficiency for over 100 years.

Solving global climate challenges today

InEpact is the pioneer in transforming low-grade waste heat into clean, emission-free electricity. Based on InEpact’s patented rotor machine technology, they combine innovation and technology development with competitive manufacturing on a larger industrial scale for the global market. InEpact’s heat-to-electricity technology is unique and contributes to solving today’s global climate challenges.

Kieron Loy, Group Marketing and Sales Manager, said: “Looking back, we feel comfortable looking forward. We have a desirable heritage, and within our network of sister companies, we have a deep pool of knowledge and experience second to none. Our accumulated knowledge and experience are helping the HEMOS project to revolutionise ships’ heat energy management and work towards decarbonising the shipping industry.”

Loy is convinced that in the next few decades, renewable energy production, and efficient and smart energy use, will increasingly dominate energy systems around the world. “We are entering a time characterised by transformation. Reducing emissions and improving processes are already crucial for a competitive advantage. InEpact is a part of this transformation by delivering innovative, proven solutions that are a safe investment in uncertain times.”